Measurement of vibrations of equipment is very important because the equipment should withstand the stated level of vibration which happens during any process but in every industry. Vibration monitoring is carried out on important machines such as power stations turbines and generators, to give o early warning of defective parts. If the vibration is beyond certain level which the equipment cannot withstand, then it very lead to equipment failure.

Vibrations are sinusoidal displacement of the vibrating member about its mean position. The quantities to be measured in a vibrating system are displacement, velocity and acceleration. Measurement of vibration is made with a transducer which is sensitive to displacement, velocity or acceleration.

Accelerometer is used for vibration measurement. Accelerometer output is fed to either recorder or to display devices.

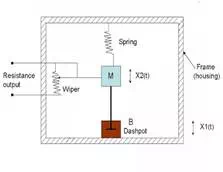

The above figure shows the potentiometric type accelerometer. The seismic mass is attached to the wiper arm of resistance potentiometer. The mass is connected to the source of vibration whose characteristics are to be determined. Relative motion of mass with respect to the transducer frame is sensed either as a change in resistance or as a change in voltage output if the potentiometer is used as potential divider. The damping is provided by dash pot. Proper damping is necessary because it increases the range of frequencies over which the transducer may be used.

Limitation:

It is only useful for measuring low frequency measurement.