When a rotor attached to a permanent magnet polarized at 90’ to the axis of rotation, and if the rotor is made to rotate due to the fluid velocity V, the rotating magnetic fluid will be cut by the pickup coil generating voltage pulses. The frequency of voltage pulses is proportional to flow rate. Hence the measure of frequency of voltage pulses becomes a measure of flow rate.

Description of Turbine Meter:

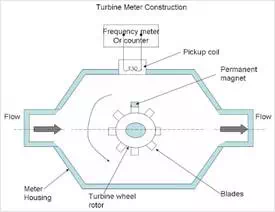

The main parts of the turbine meter are as follows:

A turbine wheel (rotor)

A permanent magnet polarized at 90’ to the axis of rotation which is attached to one of the blades of the rotor.

A pickup coil placed external to the meter housing.

A frequency meter or counter attached to the pickup coil.

Operation of Turbine Meter:

The turbine meter is fixed to the pipe carrying the fluid whose volume flow rate is to be measured.

The fluid strikes the blades of the rotor and makes it to rotate. When the rotor rotates, the permanent magnet attached to the rotor blade also rotates, which in turn produces a rotating magnetic field.

Each time the magnet passes the pickup coil, the magnetic flied is being cut generating a voltage pulse. The frequency of voltage pulses is indicated by a frequency meter.

This frequency of voltages pulses becomes a measure of flow rate when calibrated.

The volume flow rate “Q” is given by Q = F/C

Where F = total number of pulses

C = flow Coefficient

Applications:

They are extensively used in weather stations to measure wind velocity.

They are used to measure water flow in rivers and streams.

Compact models are used to measure flow in tubes and pipes.

Advantages of turbine Meter:

Recording and controlling can be done from a distance (telemetry).

High accuracy (error is -/+ 0.5%).

Has good dynamic response.

The pressure drop in the fluid is low.

It is easy to install and maintain.

Limitations of turbine meter:

Error increases if the flow rate is low.

Bearing friction and wear may alter the linear output of this instrument.

For a distance, a straight run of pipe ahead of instrument is required.