These strain gauges are not directly bonded (that is, pasted) onto the surface of the structure under study. Hence they are termed as unbonded strain gauges.

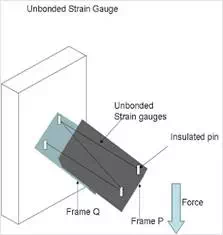

Description of the Unbonded Strain gauges:

The arrangement of an unbonded strain gauges consists of the following. Two frames P and Q carrying rigidly fixed insulated pins as shown in diagram. these two frames can move relative with respect to each other and they are held together by a spring loaded mechanism. A fine wire resistance strain gauge is stretched around the insulated pins. The strain gauge is connected to a wheatstone bridge.

Operation of Unbonded strain gauges:

When a force is applied on the structure under study (frames P & Q), frames P moves relative to frame Q, and due to this strain gauge will change in length and cross section. That is, the strain gauge is strained. This strain changes the resistance of the strain gauge and this change in resistance of the strain gauge is measured using a wheatstone bridge. This change in resistance when calibrated becomes a measure of the applied force and change in dimensions of the structure under study.

Application of Unbonded strain gauge:

Unbonded strain gauge is used in places where the gauge is to be detached and used again and again.

unbonded strain gauges are used in force, pressure and acceleration measurement.

Advantages of Unbonded strain gauge:

● The range of this gauge is +/- 0.15% strain.

● This gauge has a very high accuracy.

Limitation of unbonded strain gauges

It occupies more space.