Definition of SAYBOLT VISCOMETER

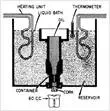

A device used to measure the viscosity of a fluid. The saybolt viscometer controls the heat of the fluid and the viscosity is the time is takes the fluid to fill a 60cc container.

Efflux cup viscometers are most commonly used for fieldwork to measure the viscosity of oils, syrups, varnish, paints and Bitumen emulsions. The testing procedure is quite similar to the capillary-tube viscometers where efflux time of a specified volume of fluid is measured through fixed orifice at the bottom of a cup to represent the viscosity of the fluid. Since the viscosity of Newtonian liquid are independent of dimensions of viscometer used, it is possible to convert the efflux times to kinematic viscosities by conversion charts or by formulas suggested by the equipment manufacturers.

To obtain high accuracy the liquid holding vessel and orifice are temperature controlled by immersing them in a thermostatically controlled bath. The saybolt viscometer, one of the efflux cup viscometers is the standard instrument for testing petroleum products. There are three types of orifices available-Universal, Furol, Asphalt.

The furol and asphalt orifices, respectively, have an efflux time of approximately, one-tenth and one-hundredth that of the universal orifice. The cup orifice combination should be selected to provide an effllux time within the range of 20 to 100 seconds. Of these types, the universal orifice(saybolt universal viscometer) is most commonly used and its efflux time is designated as saybolt universal seconds(SUS).The universal viscometer measures the time required for 60 cc of sample fluid to flow out through an orifice having dimensions of 0.176 cm in diameter and 1.225 cm in length. Saybolt universal seconds (t) can be converted to kinematic viscosity (v) by the following equations:

When t < 100 secs, v = 0.226t – 195/t Centistokes

When t >100 secs, v = 0.220t – 135/t Centistokes

The viscosity determinations should be conducted in a room free from drafts and rapid changes in temperature the highest degree of accuracy.