The process of lithographically fabricating microcomponents is analogous to printing a photograph in a darkroom. In phorography, an energy sensitive material (photo emulsion) is placed as a thin coating on a piece of photographic paper. A negative is used to selectively transmit or block energy (light) passing from a source to the emulsion. The light causes a chemical change in the emulsion which changes its properties in certain developers. The exposed picture undergoes chemical processing and the emulsion is then fixed to stabilize it against further exposure by ambient light.

The process of lithography is also used to fabricate a variety of microcomponents and systems such as electronics, air bag accelerometers, inertial guidance sensors, and pressure and flow sensors, for example. The process is very much like that described above, but has been specially tailored to the particular application. There are two basic types of lithography used to make microsctructures. They are optical and x-ray lithography. Microlithography has generally used terms which show the analogy with photography.

| Photoresist | the energy sensitive material into which the pattern of the microstructures is transferred (similar to photograpic emulsion) |

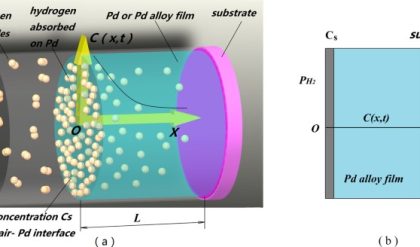

| Substrate | the structural carrier for the photoresist, often times silicon but is application dependent (similar to photographic paper) |

| Mask Substrate | the portion of the mask which is transparent to the exposing energy and which carries the energy absorber (like cellulose film/clear portion of photographic negative) |

| Mask Absorber | the mask material which is patterned to selectively block energy from reaching the photoresist (dark portion of photographic negative) |

| Collimated Source | the energy source used to transfer the mask pattern into the photoresist by way of parallel energy rays (like the condenser and light in a photographic enlarger) |

| Developer | the chemical used to dissolve the photoresist which has either been exposed to the energy or has been blocked from being exposed to the energy (like the many types of photographic developers) |

| Photoresist Tone | the nature of the specific photoresist used such that it becomes soluble or insoluble in certain developers upon exposure. A resist that can be developed away upon exposure is termed a “positive resist” and one that becomes insoluble (cures) upon exposure and remains is a “negative resist.” Negative resists are similar to photocuring resins. |

Comments are closed.