Lord Kelvin’s oft-quoted statement may bear repeating here:

I often say that when you can measure what you are speaking about, and can express it in numbers, you know something about it; but when you cannot measure it, cannot express it in numbers, your knowledge is of a meager and unsatisfactory kind; it may be the beginnings of knowledge, but you have scarcely, in your thoughts, advanced to the stage of science, whatever the matter may be. So therefore, if science is measurement, then without metrology there can be no science.

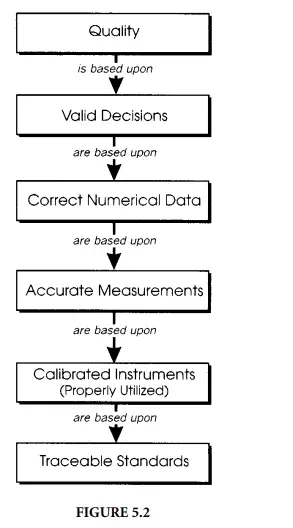

Lord Kelvin’s statement has been quoted so many times that it has almost become trite, but looking at Figure 5.2 will show an interesting hierarchy. In order to achieve quality or “to do things right,” it is necessary to make some decisions. The correct decisions cannot be made unless there are good numerical data on which to base those decisions. Those numerical data, in turn, must come from measurements and if “correct” decisions are really needed, they must be based on the “right” numbers. The only way to get “good” numerical data is to make accurate measurements using calibrated instruments that have been properly utilized. Finally, if it is important to compare those measurements to other measurements made at other places and other times, the instruments must be calibrated using traceable standards.

The Need for Standards

Standards define the units and scales in use, and allow comparison of measurements made in different times and places. For example, buyers of fuel oil are charged by a unit of liquid volume. In the U.S., this would be the gallon; but in most other parts of the world, it would be the litre. It is important for the buyer that the quantity ordered is actually received and the refiner expects to be paid for the quantity shipped. Both parties are interested in accurate measurements of the volume and, therefore, need to agree on the units, conditions, and method(s) of measurement to be used.

Persons needing to measure a mass cannot borrow the primary standard maintained in France or even the national standard from the National Institute of Standards and Technology (NIST) in the U.S. They must use lower-level standards that can be checked against those national or international standards. Everyday measuring devices, such as scales and balances, can be checked (calibrated) against working level mass standards from time to time to verify their accuracy. These working-level standards are, in turn, calibrated against higher-level mass standards. This chain of calibrations or checking is called “traceability.” A proper chain of traceability must include a statement of uncertainty at every step.

Types of Standards

Basic or Fundamental Standards

In the SI system, there are seven basic measurement units from which all other units are derived. All of the units except one are defined in terms of their unitary value. The one exception is the unit of mass. It is defined as 1000 grams (g) or 1 kilogram (kg). It is also unique in that it is the only unit currently based on an artifact. The U.S. kilogram and hence all other standards of mass are based on one particular platinum/iridium cylinder kept at the BIPM in France. If that International Prototype Kilogram were to change, all other mass standards throughout the world would be wrong.

The seven basic units are listed in Appendix 1, Table 1. Their definitions are listed in Appendix 1, Table 2.

Derived Standards

All of the other units are derived from the seven basic units described in Appendix 1, Table 1. Measurement standards are devices that represent the SI standard unit in a measurement. (For example, one might use a zener diode together with a reference amplifier and a power source to supply a known voltage to calibrate a digital voltmeter. This could serve as a measurement standard for voltage and be used as a reference in a measurement.)

Appendix 1, Table 3 lists the most common derived SI units, together with the base units that are used to define the derived unit. For example, the unit of frequency is the hertz; it is defined as the reciprocal of time. That is, 1 hertz (1 Hz) is one cycle per second.

The Measurement Assurance System

Figure 5.3 illustrates the interrelationship of the various categories of standards throughout the world. While it gives more detail to U.S. structure, similar structures exist in other nations. Indeed, a variety of regional organizations exist that help relate measurements made in different parts of the world to each other.