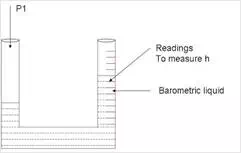

A well known very simple device used to measure the pressure is the U-tube manometer. The name U-tube is derived from its shape. U-tube manometer is shown below,

Construction of U-tube Manometer:

Let me explain you about the construction about the u-manometer. This manometer consists of a U shaped tube in which the manometric liquid is filled. The manometer is used to measure the pressure which is unknown by the balancing gravity force and acceleration due to gravity, g = 9.81 m/sec2

The manometer consists of a steel, brass and aluminum material. It has a glass tube made up of pyrex glass. The graduations are made on the tube in terms of mm or in some condition it is graduated in kilo Pascal.

Working of U-tube Manometer:

The unknown pressure is applied in the one arm of the tube and the mercury in the tube or manometeric liquid filled in the tube moves in the tube or rises to the constant region and then the movement is stopped. The height of the liquid is measured and noted. The pressure is calculated by using the formula,

P1-P2 = Pmhg

The above equation is arrived by

P1 = Pthg = P2+Pmhg

P1-P2 = hg(Pt – Pm)

P1 = applied pressure

P2 = 0

Pt = specific gravity of the liquid or water

g = acceleration due to gravity.

P1 – P2 is approximately equal to Pmhg.

Advantages of U-tube Manometer:

1. Simple in construction

2. Low cost

3. Very accurate and sensitive

4. It can be used to measure other process variables.

Disadvantages of U-tube Manometer:

1. Fragile in construction.

2. Very sensitive to temperature changes.

3. Error can happen while measuring the h.

Characteristics of liquid used in U-tube Manometer:

1. Viscosity should be low.

2. Low surface tension is required.

3. The liquid should stick on the walls.

4. Should not get vaporized.