A sight glass (also called a gauge glass) is used in the liquid level measurement. It is used for continuous indication of liquid level within a tank or vessel.

Construction and working of Gauge Glass Technique:

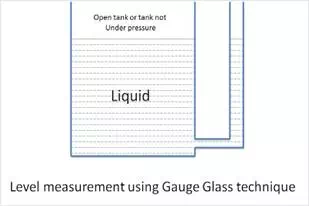

A sight glass instrument consists of a graduated tube of toughened glass which is connected to the interior of the tank at the bottom whose water level is to be measured. The image below shows a simple sight glass for an open tank in which the liquid level in the sight glass matches the level of liquid in the tank.

As the level of liquid in the tank rises and falls, the level in the sight glass also rises and falls accordingly. Thus by measuring the level in the sight glass, the level of liquid in the tank is measured.

When it is desired to measure a liquid level with the liquid under pressure or vacuum, the sight glass must be connected to the tank at the top as well as at the bottom, otherwise the pressure difference between the tank and the sight glass would cause false reading. In this case, the glass tube is enclosed in protective housing, and the two valves are provided for isolating the gauge from the tank in case of breakage of the sight glass. The smaller valve at the bottom is provided for blowing out the gauge for cleaning purpose.

|

| Pressure balance is obtained at any points in the fluid which are at equal distances above or below some reference. If the liquids are subjected to the some external pressure and have the same specific gravity, the level will be the same in both vessels. |

The image below shows a high pressure sight glass in which measurement is made by reading the position of liquid level on the calibrated scale. This type of sight glass in high pressure tanks is used with appropriate safety precautions. The glass tube must have a small inside diameter and a thick wall.

|

| When the liquid in the tank is under some external pressure, the pressure can be nullified by connecting the sight glass as indicated. |

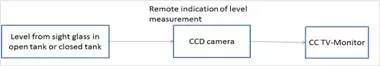

Remote indication

Liquid level in either open tank or closed tank can be measured by sight glass or gauge glass technique. It can be controlled by the operator in the control room by means of monitoring the sight glass fixed at different places of tank with the help of CCTV system. OCD camera is focused at the sight glass or gauge glass and viewed in the control room through a monitor. The image below illustrates the block diagram of the remote indication of level measurement.

Ranges of gauge glass:

The standard practice is not to go in for a glass tube of more than 900mm length. In case the height of the tank is more than 900mm, two or more sight glass level gau ges are provided at different levels. This type of gauge is made to withstand pressures of 150 kg/cm^2 of steam pressures at 250’C or 450kg/cm^2.

Advantages of gauge glass:

1. Direct reading is possible.

2. Special designs are available for use upto 3000’c and 650 kg/cm^2.

3. Glassless designs are available in numerous materials for corrosion resistance.

Disadvantages of gauge glass:

1. The main disadvantage is that, it is read where the tank is located which is not always convenient.

2. Since sight glasses are located outside the tanks, the liquid in the sight glass may freeze in cold weather even though the liquid inside the tank does not, and thus, it may cause error in the reading.

3. Heavy, viscous liquids or liquids containing material which fall out of solution and clog the tube cannot be measured satisfactory by sight glass.

4. Overlapping gauges needed for long level spans.

5. Accuracy and readability depends on cleanliness of glass and fluid.