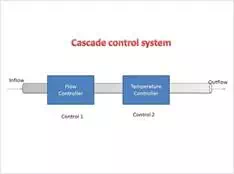

It there is more than one control systems are added together in a process the control system is called cascade control system.

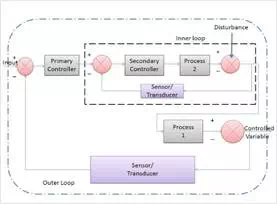

Block diagram of cascade control system

The inherent interaction that occurs between two control systems in many applications is used in one control loop determined by measurement of a different variable for which interaction exists.

Two measurements are taken from the system. Each is used in its own control loop. Set point of inner loop is decided by controller output of outer loop. Cascade control provides better control of the outer loop variable than is accomplished through a single variable system.

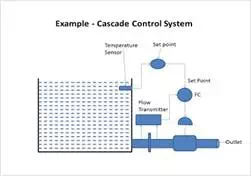

Example of Cascade control system

The temperature controller generates the correction signal based on the actual temperature. This correction signal is used as the set point input to a flow controller. The flow controller signal positions the control valve, which regulates the flow of hot liquid from the vessel.

If temperature of heating tank fluid rises above the set point the temperature controller generates pneumatic signal which acts as the set point to the flow controller. Flow controller closes the control valve that decreases the flow of heating fluid so as to get the desired heating effect. Similarly the heating fluid temperature falls below the desired heating effect.

Advantages of cascade control system

The flow controller is much faster than the temperature controller due to much shorter dead time in the secondary loop than in the original single loop system.

The temperature controller with an integral mode remains in the design to ensure zero for all disturbance source.

Comments are closed.