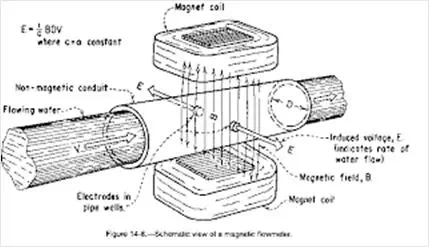

Basic principle:

When a flowing conducting fluid is subjected to a transverse magnetic field, the flowing conducting fluid cuts the magnetic field and causes a voltage to be induced. This induced voltage is proportional to the fluid velocity, that is, flow rate.

Construction of Magnetic flow meter:

The main parts of this instrument are as follows:

A conducting fluid is flowing through a non-magnetic and non-conducting pipe, whose flow rate is to be measured.

Two electrodes are attached in opposite sides of pipe carrying the conducting fluid. These electrodes are in contact with the flowing conducting fluid.

The pipe is surrounded by an electromagnet which produces which produces a magnetic field.

Operation of a Magnetic Flow Meter:

This magnetic flow meter is based on faraday’s law of induced voltage which is given as follows,

E = BLV

Where,

E = induced voltage(volts)

B = flux density (gauss)

L = Length of conductor which is the diameter of the pipe (cm)

V = Average velocity of conductor (fluid) in cm/sec

When the conducting fluid flows through the pipe which is subjected to a magnetic field, the conducting fluid cuts the magnetic field and due to this a voltage is induced. As the magnetic field is constant, voltage obtained across the electrodes will be directly proportional t average fluid velocity and diameter (length) and hence becomes a measure of volume flow rate.

Applications of a Magnetic Flow Meter:

Used to measure flow rates of conducting fluids.

Used to measure flow rates of slurries, corrosive and abrasive fluids.

Magnetic flow meter is used to measure bidirectional flows by reversing connections which can be done automatically.

Advantages of magnetic flow meter

These meters do not cause obstruction to flow and hence cause no pressure drop.

For measurements, it does not matter whether the flow is laminar or turbulent.

It gives accurate results.

Its reliability is high, that is, it gives a standard performance for an elongated period of time.

It can handle greasy materials and fluids containing suspended solids.

The measurement is independent of viscosity, density, temperature and pressure.

Limitations of Magnetic Flow Meter:

The fluid whose flow rate is to be measured should satisfy certain conduction conditions.

The fluid should be full in the pipe to get accurate results.

Air and gas bubbles in the fluid will cause errors.

When certain fluids, the electrodes might get coated with scales and this will affect the output signal. However, this can be taken care off by cleaning the electrodes.

In many cases, the output voltage is low and hence requires amplification.