Basic Principle of Flow Nozzle:

When a flow nozzle is placed in a pipe carrying whose rate of flow is to be measured, the flow nozzle causes a pressure drop which varies with the flow rate. This pressure drop is measured using a differential pressure sensor and when calibrated this pressure becomes a measure of flow rate.

Description of Flow Nozzle:

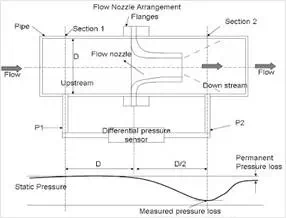

The main parts of flow nozzle arrangement used to measure flow rate are as follows:

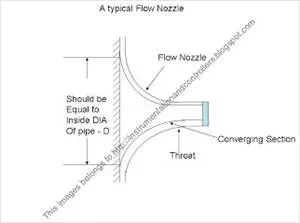

1. A flow nozzle which is held between flanges of pipe carrying the fluid whose flow rate is being measured. The flow nozzle area is minimum at its throat.

2. Openings are provided at two places 1 and 2 for attaching a differential pressure sensor (u-tube manometer, differential pressure gauge etc.,) as show in the diagram.

Operation of flow Nozzle:

1. The fluid whose flow rate is to be measured enters the nozzle smoothly to the section called throat where the area is minimum.

2. Before entering the nozzle, the fluid pressure in the pipe is p1. As the fluid enters the nozzle,the fluid converges and due to this its pressure keeps on reducing until it reaches the minimum cross section area called throat. This minimum pressure p2 at the throat of the nozzle is maintained in the fluid for a small length after being discharged in the downstream also.

3. The differential pressure sensor attached between points 1 and 2 records the pressure difference (p1-p2) between these two points which becomes an indication of the flow rate of the fluid through the pipe when calibrated.

Applications of Flow Nozzle

1. It is used to measure flow rates of the liquid discharged into the atmosphere.

2. It is usually used in situation where suspended solids have the property of settling.

3. Is widely used for high pressure and temperature steam flows.

Advantages of flow Nozzle

1. Installation is easy and is cheaper when compared to venturi meter

2. It is very compact

3. Has high coefficient of discharge.

Limitations

1. Pressure recovery is low

2. Maintenance is high

3. Installation is difficult when compared to orifice flow meter.