This thermometer is an instrument used to measure the temperature variation in control room.

Working principle

In each metallic conductor, their resistance changes when its temperature is changed. By calculating the variation in resistance, the temperature variations may be calculated. The thermometer which utilizes this phenomenon is called “resistance thermometer”.

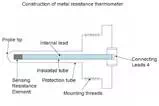

Construction

The construction of resistance thermometer detector is shown in figure. RTD uses platinum, nickel or copper as a resistance element. Generally, platinum wire is wound on either ceramic bobbin toform a resistance element. This resistance element is placed inside the hollow structure called protection tube. It is made up of stainless steel or carbon steel.

Internally lead wire is used to connect resistance element with external lead terminals. Lead wire covered by insulated tube for short circuit prevention. Fiberglass is used for low and medium temperature and a ceramic insulation for high temperature.

Protection tube is used to protect the resistance element and internal lead wires from ambient conditions. Protection tube is fitted with the mounting attachment to install the resistance temperature detector to measuring point.

Operation

Initial resistance is measured by using wheatstone bridge. Probe tip of the RTD is placed near the heat source. Outer cover uniformly distributes heat to sensing resistance element. As the temperature varies, the resistance of the material also varies. Now, final resistance is again measured. From the above measurement, variation in temperature can be calculated as follows,

Rt = R0 ( 1+Dt)

Dt = ( (Rt/R0)-1)/x

Where,

Rt = resistance at C.

R0 = Resistance at room temperature.

Dt = Difference in temperature.

X = Temperature coefficient of RTD material.

Thus from the above formula by knowing Rt, R0 and x, the difference in temperature can be calculated.

Advantages

Accuracy is more.

More linear than thermocouple.

No necessary for temperature compensation.

Performance is stable for long period.

Disadvantages:

Expensive.

Their change in temperature is very small even for large change in input temperature.

External current source is required.

Low sensitivity.