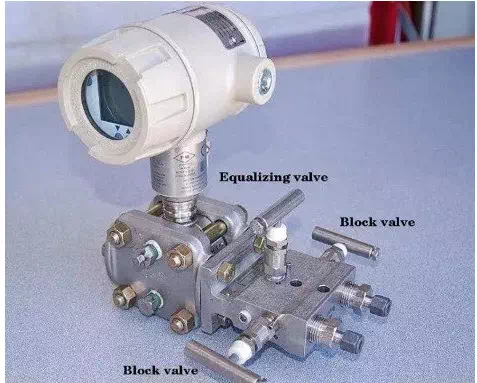

Manifold provide a convenient interface for fluid or gas distribution. There are several factors that must be considered before selecting a pneumatic manifold.

Material:

Pneumatic maifolds are produced from a variety of metals and plastics, so it is important to know which material in your application is compatible with the media.

The selection of an incompatible material can lead to the leakage of the manifold at the distribution point in your system.

Port Size:

Manifolds offer a variety of input and output porting options for the control valves and fittings required for an application.

Be sure to select components with the same thread size to speed the installation in the output ports of the collector when designing your fluid control circuit.

Number of Stations:

Most standard collectors have two to 10 stations, but customized collectors can be produced to accommodate the required number of components in your circuit.

Spacing:

The spacing between the output ports of the manifold is one of the most commonly forgotten elements of multiple selection.

When selecting a collector, you want to make sure that the control valves or fittings can be installed without interfering with an adjacent component.

Operating Pressure:

Different materials have different limitations on pressure. Check the manufacturer’s published operating pressures to ensure that when used in your application, the variety does not break

Placement:

Consider where the collector will be placed in your system. The closer the collector assembly is to your equipment, the fewer long lines need to be run, saving money and providing plumbing comfort.