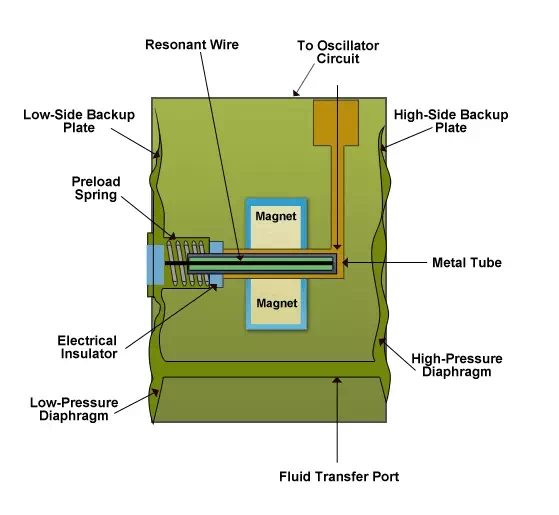

The resonant – wire pressure transducer is a device that is generally used in industrial applications to measure pressure. It was released in the late seventies. There are: in this design:

Working of Resonant Wire Pressure Transducer:

A wire is fixed at one end by a static member in a resonant wire pressure transducer and at the other end by a pressure sensing diaphragm (under tension).

High pressure and low pressure diaphragms on the right and left of the unit detect the process pressures. The wire is placed in a magnetic field and permitted to oscillate. The oscillator circuit results in resonant frequency wire oscillation.

The variations in process pressure affect the tension of the wire, which also changes the wire’s resonant frequency.

For example, the element increases the tension in the wire as the pressure increases, thus increasing its resonant frequency. For detecting the shift, a digital counter circuit is used.

Since this change in frequency can be detected accurately to a certain extent, this type of transducer can be employed for low differential pressure applications as well as to detect absolute and gauge pressures.

Advantages:

· Good repeatability

· Less hysteresis

· Good accuracy

· Strong output signal