The short answer is that when Don Bently worked on building solid-state versions of the eddy-current measuring system, he had a choice between using N-P-N or P-N-P transistors. Transistors were quite expensive at the time, so he chose the two least expensive: P-N-P

The PNP transistors used by the circuits required a negative bias voltage rather than a positive bias voltage. Don opted for -18V. This was later changed to -24V to give the transducer more linear range.

The industrial instrumentation community had not yet standardized on+ 24 vdc at that time, and by the time they did, so many Bently Nevada eddy current vibration sensors were installed that users were not enthusiastically welcoming the change to+ 24V rather than-24V. Therefore, to this day it has remained-24V.

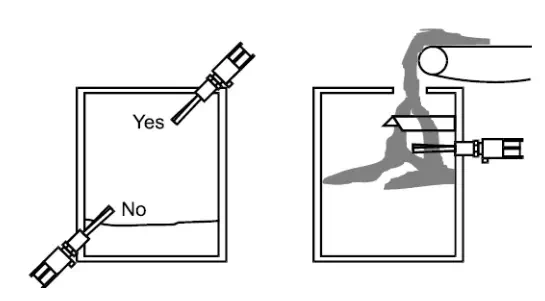

An eddy-current probe works by passing through a coil of wire an alternating current and measuring the impedance of the coil. This impedance changes when the probe comes close to an electrically conductive material and the change in impedance is proportional to the physical gap between the coil and the conductive target.

In turn, the sensing electronics convert this impedance change into a voltage, providing a directly proportional electrical output to the physical gap that is directly proportional to the vibration.