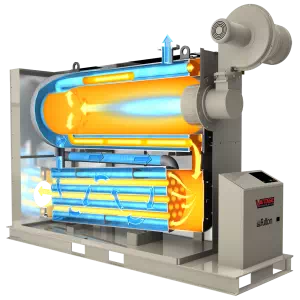

Hydronic boilers are frequently applied in residential & commercial buildings for heating purposes.

They are usually manufactured in small sized portable units for domestic applications whereas large sized units are put into use for industrial applications.

These boilers are extremely durable and provide a long service life. Furthermore, their use is less complicated than other heating systems. However, the hydronic boiler installation procedure is quite expensive.

Working:

The fuel is inserted into a pressurized tank where the combustion process takes place in a typical hot water boiler system.

The system includes a temperature control device called a thermostat that keeps a fuel temperature check. Within the pressurized tank, the water is supplied in combination with a regulated amount of air that starts the process of burning the fuel.

Types of Hot water boiler system:

Closed system: The water evaporated and converted into steam is restored to use in these types of systems by condensing the steam back into liquid form. This means that the water is 100 percent reused in closed systems.

Open system: The water is heated in these systems, but the evaporated water is not put back into the system for reuse.

Single – pipe system: two pipes are used in these systems. One pipe is used to transport the heated water to the required location, while the second pipe is used by means of a motorized pump to return the cool water back to the boiler.

Gravity System: These are the older hot water boiling systems in which the water is carried back after heating via the gravity effect. Hence, in these systems, circulators are not required .