INTRODUCTION

The study of any subject matter in engineering should be motivated by an appreciation of the uses to which the material mightbeput in the every day practice of the profession. Measurement syst.emsareused for many detailed purposes in a wide variety of application areas. The easiest way to assess the amount of’ vusc of science and technology is to I examine the number of measurements that arc being made and how they are being used. All the successful achievements in science and technology are entirely due to the ability to measure the state, condition or characteristics ofthe physical.systems, in quantitative terms with. sufficient accuracy.Lord-Kelvin stressed the importance of measurement in this context, by saying: “Wh.en you can measure what you are speaking about, and express it in numbers, you know something about it”.

MEASUREMENT

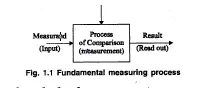

The measurement is usually undertaken to ascertain and present the state, condition or characteristic of a system in quantitative terms. To reveal the performance of a physical or chemical system~ the’ first operation carried out on it is measurement. The process or the act of measurement consists of obtaining a quantitative comparison between a pre defined standard and a measurand. The word measurand is used to designate the particular physical parameter being observed and quantified that is, the input quantity to .the measuring process.

Measurements are generally made

• to ‘understand an eventor an operation, to monitor an event or an operation.

• to control an event or an operation.

• to collect data for future analysis and

• to validate an engineering design.

Fig, 1.1 shows the fundamental measuring process

Fundamental methods of measurement

There are two basic methods of measurement

1. Direct comparison with either a’ primary or a secondary standard.

2. Indirect comparison through the use of a calibrated system.

Direct comparison

To measure the length of a bar, we compare the length of the bar with a .standard, and find that the bar is so many inches long because that many , inch-units on the standard has the same length as the bar. Thus we have determined the length by direct comparison. The standard that w~ have used is called a secondary standard. Measurement by direct comparison is less

common than the measurement by indirect comparison.

Indirect comparison

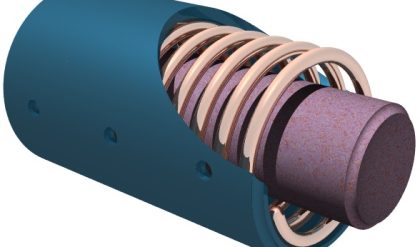

Indirect comparison makes use of some form of transducing device. This device converts the basic form of input in ~o ananalogous form, which it then processes and presents at the output as a known function of the input.

Functional elements of a measurement system

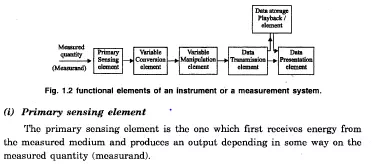

Fig. (1.2) shows the functional elements of an instrument or a measurement

system.

(ii) Variable conversion element

Tho output signal of the primary sensing element is some physical variable, such as displaceme.nt or voltage. For the instrument to perform the desired function, it maybe necessary to convert this variable to another more suitable variable while’ preserving the information content of the originalSIgnal:’,—An element that performs such a function is called a variable conversion clement

(iii) Variable manipulation element

The element that performs “manipulation” by which the numerical value of the variable is changed according to some definite rule but the physical nature of the variable is ‘preserved is called a variable-manipulation element.

(iu) Data-transmission element

When the functional elements of an instrument are actually physically separated, it becomes necessary to transmit the data from on.e to another. An element performing this function is called a data-transmission element.

(v) Data-presentation.

Element If the information .about the measured quantity is to be communicated to a human being for monitoring, control, or analysis purposes, it must be put in to a form recognizable by one of the human senses. An element that performs this “translation” function is called ~ata:”presentationelement. This function includes the simple indication of a pointer-moving over a scale and the recording of a pen moving over a chart

(vi) Data storage/playback element

Althou.gh ·data storage in the form of pen/ink recording is often employed, some applications require a distinct data storage/play back function which can easily recreate the stored data upon command. The magnetic tape recorder/reproducer is the example.

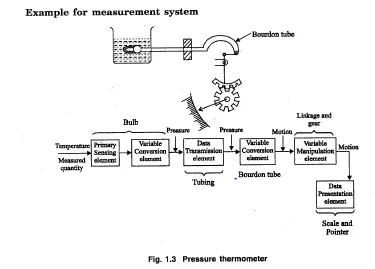

As an example of the above concepts, consider a pressure type thermometer [sec fig (I..8)]. The liquid-filled bulb acts as a primary sensor and variable-conversio~clement since a temperature change results in a pressure build up with in the bulb, because of the constrained thermal expansion of the filled fluid.

This pressure is. transmitted through the tube to a Bourdon-type pressure gaugevwhich converts pressure to displacemen~. This displacement is manipulated by the linkage and gearing to give a larger pointer motion. A scale and pointer again ‘serve for data presentation.