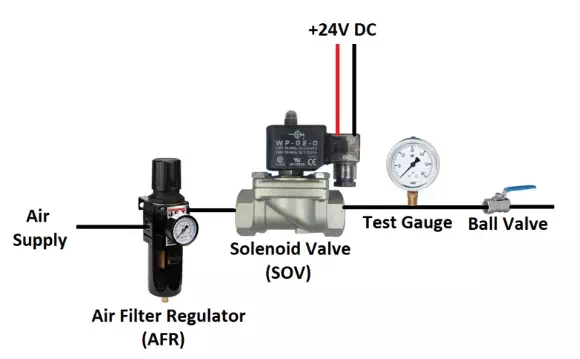

Here we look at, how functional test is done for solenoid valve using instrument air.

Solenoid Valve Testing:

· Air supply is connected to the Air Filter Regulator (AFR).

· Set the stress required in the AFR and link the AFR outlet to the Solenoid valve.

· Connect outlet of Solenoid Valve to a Ball valve.

· Connect a pressure gauge at the Solenoid Valve outlet.

· The aim of Test Gauge is to verify the inlet line stress depends on SOV energy.

· Ball valve used to stop the functional testing

Typical Solenoid valve Test Set-up:

· Check the nameplate for the manufacturer/instrument datasheet. Confirm the voltage / current scores of the solenoid valve (consider + 24V DC device in our instance)

· Check the solenoid valve port configuration.

· Hook-up tool according to the typical sample configuration.

· Apply air-specified valve port stress and link 24VDC to valve terminals with solenoid.

· Switch on the 24VDC energy supply, inspect the energy valve by controlling the stress of the sample gage (increasing pressure).

· Turn off the supply. Confirm the de energized valve, inspect the value of the sample gage again (Diminishing stress)

· Tabulate all result in Check Sheet.