Fluid pressure can exert in the storage tanks, as described by the formula F = PA. One practical consequence of this is that process vessels and pipelines can burst catastrophically if they are subjected to excessive fluid pressure.

Some vessels and piping may implode if they are subjected to excessive vacuum (collapse on themselves). These potential failures not only pose operational problems, but can also pose serious safety and environmental risks, especially if the process fluid is toxic, flammable or both.

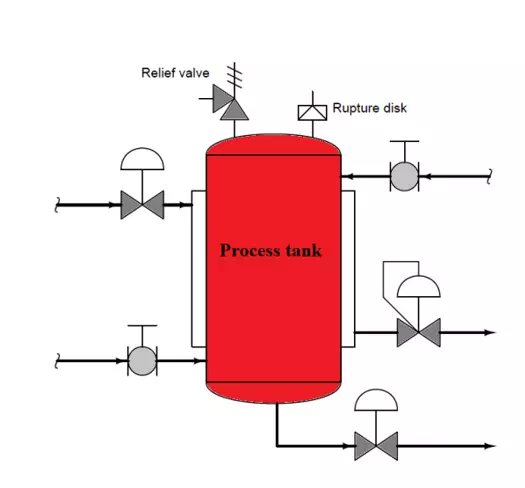

Over Pressure Protection Devices:

The following subsections describe each of these protective devices and their intended operation.

There are two types of overpressure protection devices namely, rupture disk and safety valve.

A rupture disk acts as an electrical fuse to protect against overpressure: When the burst pressure is exceeded, the disk breaks to allow fluids to escape.

Safety and relief valves function as self-resetting circuit breakers: They open to relieve pressure and then close the processingsystem again.

Piping blockages and overheating caused by fires are two common causes of process overpressure. Although it may sound ridiculous, some fatal industrial accidents were caused by something as simple as shut – off valves, which should have been left open.

If the fluid is unable to escape a process vessel, the pumping forces may exceed the vessel’s burst rating and cause catastrophic failure. Due to the expansion of process fluids in sealed vessels, fires can also cause overpressure conditions.

In such scenarios, overpressure protection devices play a key roleinventing process fluid to prevent the vessel from bursting. It should be noted that the protection requirements of these two causes of overpressure may differ greatly.

In a “fire case,” the required flow rate of the exiting fluid to safely limit the pressure may be much higher than in a “blockage case,” which means that the sized overpressure protection devices may not be sufficient to protect against the former.

The selection of overpressure protection devices is a task limited to process security engineers. The installation and maintenance of overpressure protection devices may involve instrument technicians, but only a qualified and licensed engineer should decide which specific device(s) should be used for a specific process system.